Using Consumer Displays in Industrial Environment

On paper, a consumer tablet or display panel seems like a quick solution. It’s cheap, easy to source, and looks modern during prototyping. But consumer displays are built for short product lifecycles, not 10+ years of industrial uptime.

The problem: Consumer-grade panels get discontinued in 18–24 months, forcing OEMs into redesigns that eat up 9–12 months of engineering time. They also lack ruggedization for vibration, dust, or 24/7 operation.

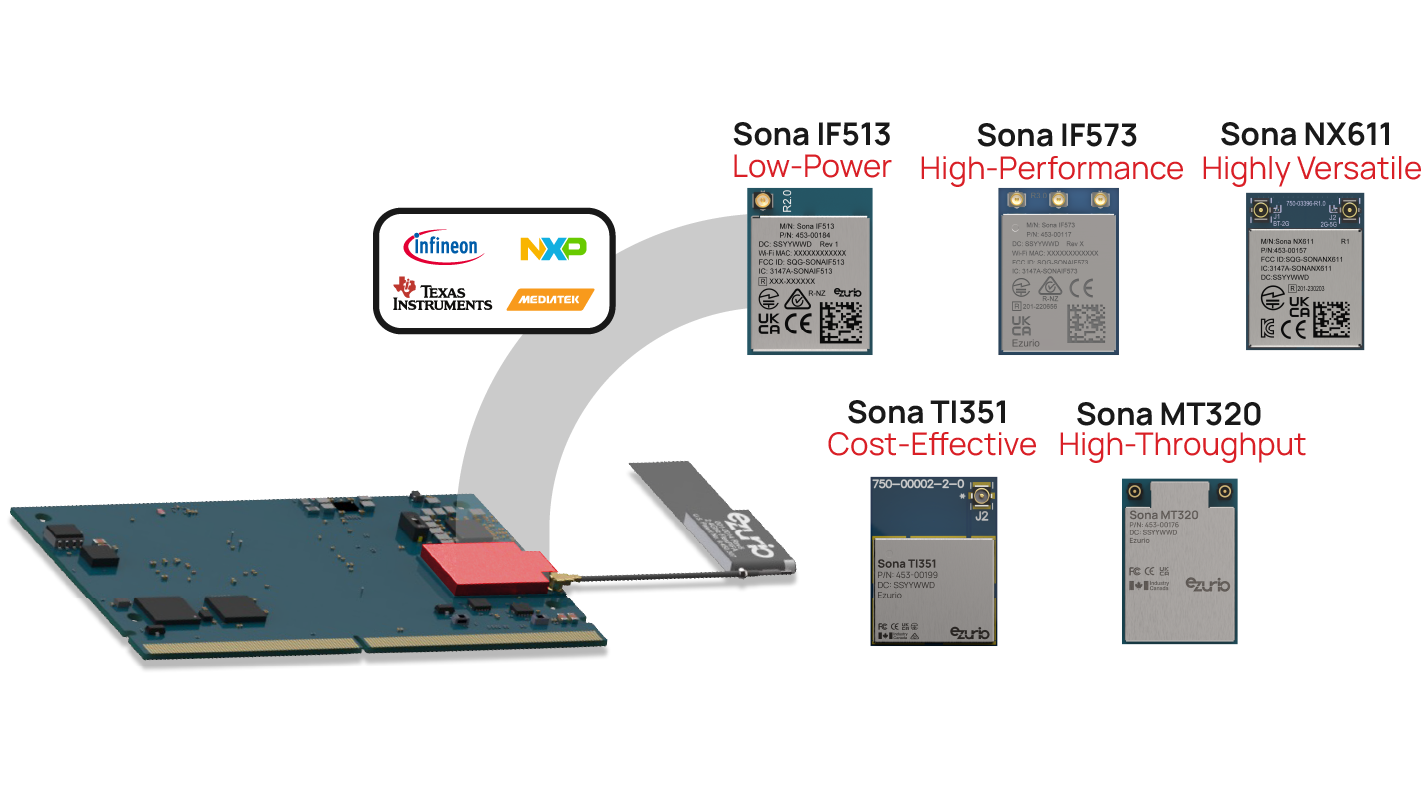

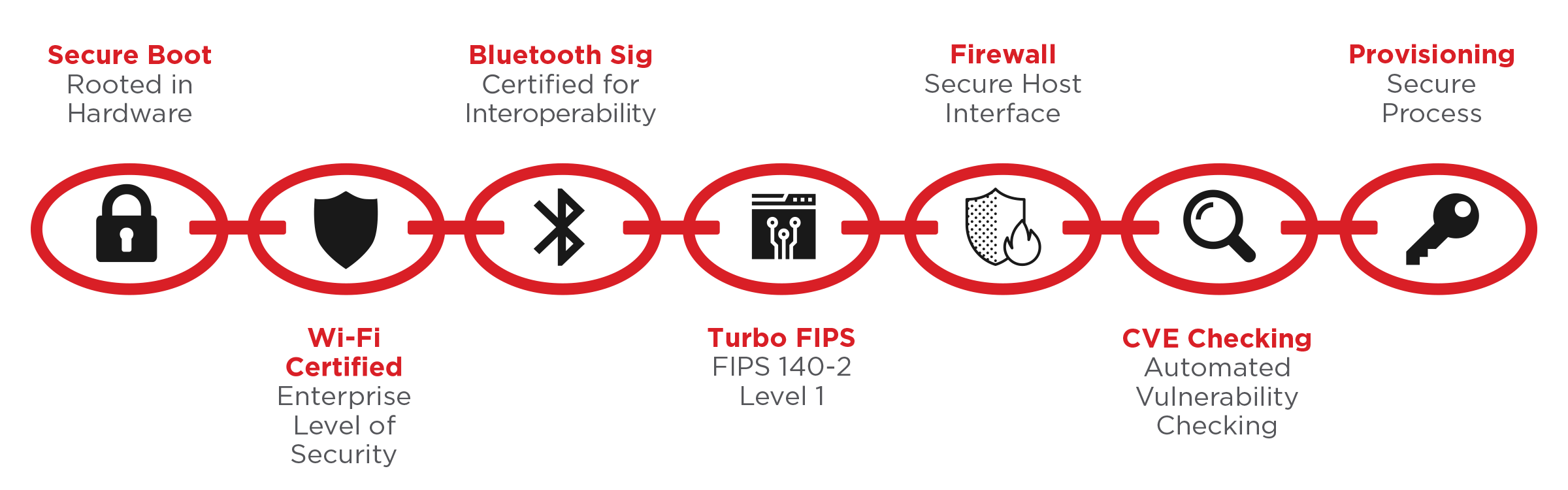

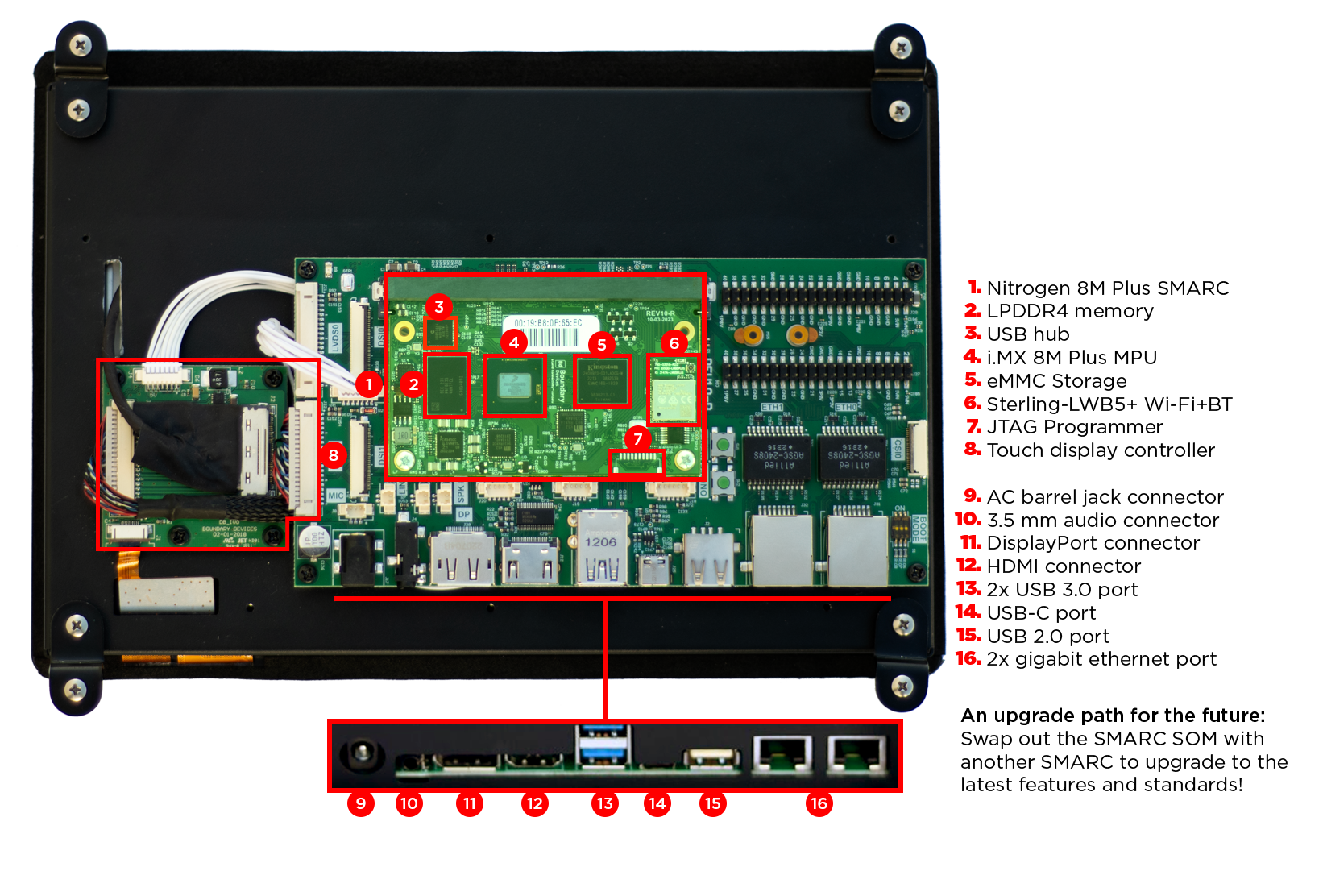

How to avoid it: Build around industrial SOM-based HMIs like Ezurio’s Nitrogen or Tungsten familes, which provide the necessary computing, connectivity, guarantees lifecycle support, and rugged designs tested for harsh environments.