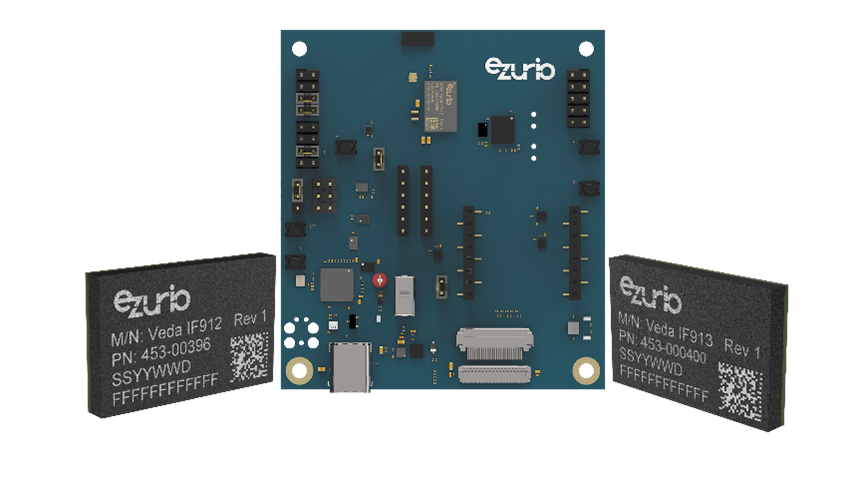

We are finally at a turning point. Connected MCUs with integrated WiFi 6 and 6E fundamentally change the architecture of connected products. Modules like Ezurio’s Veda IF912 and Veda IF913, built on Infineon’s AIROC CYW5591x silicon, represent the shift away from bolt-on wireless and toward designs where compute, memory, and connectivity finally operate as one system.

Here is why that shift is happening and what it solves.

The Pain: Bolt-On Wireless Is Not as Simple as It Looks

Customers usually come with the same set of problems:

Integration complexity snowballs quickly

That “easy” SDIO WiFi module looks fine at first, until you realize:

- Your host processor cannot keep up under load

- The driver requires specific kernel patches

- Layout constraints damage antenna performance

- You are juggling two separate firmware roadmaps

By the end, half the schedule is swallowed by issues no one planned for.

RF performance suffers because it has to fit the enclosure, not the system

Bolt-on designs force antennas into whatever space is left. That might be inside a forklift mast, behind a metal enclosure, or buried under plastic inside a medical device.

The RF problems are predictable long before they happen, and yet they still happen.

Certifications slow everything down

When wireless is a separate module, you must:

- Test the radio module for compliance

- Test the host MCU for EMI

- You have to do integration testing when you put them together

- Repeat certification again anytime the antenna changes

Teams underestimate this every single time.

The BOM cost keeps increasing

One board for the host MCU, one for wireless, external memory, custom harnesses, enclosures—by the time the full system is built, the wireless subsystem costs far exceed what the product owner expected.

And in long-lifecycle industries such as material handling, medical, and commercial HVAC, that pain compounds across entire product lines.