Benefits of SOMs include:

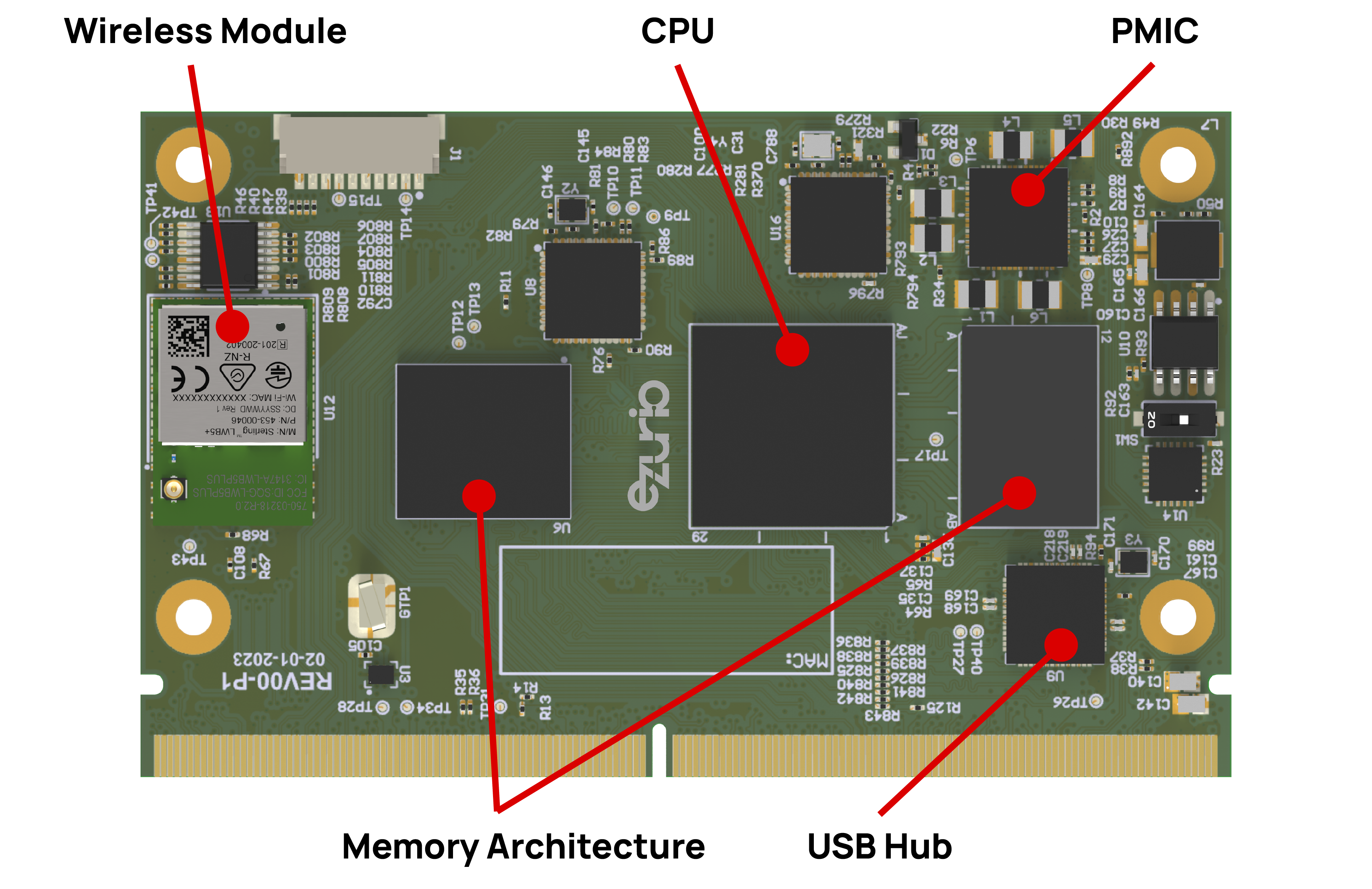

- Simplification and speed of design processes: The biggest advantage of a System-on-Module is design simplification and speed. Engineers can start with a ready-made module that packs the complex parts of the system, drastically reducing the hardware design effort needed. High-speed memory layout, wireless RF design, power sequencing – all those challenges are handled on the module. This means development teams can integrate a SoM and focus more on their specific application logic. As a result, products can be prototyped and brought to market much faster (shorter development cycle).

- Lower Development Risk: The module comes pre-validated and often pre-certified for things like wireless compliance, electromagnetic interference, and sometimes even industrial temperature ranges. For example, a SoM that includes Wi-Fi/Bluetooth may already have FCC/CE certifications, saving you the lengthy and costly process of certifying your device’s radio yourself. The SoM vendor typically provides a Board Support Package (BSP) with drivers and an operating system tuned to the hardware, which means you spend less time debugging low-level hardware issues and more time writing your application. In short, a SoM lets you focus on firmware and software development by eliminating much of the complex hardware work.

- Flexibility and scalability: Because the SoM is modular, you can often swap it out for a different one to upgrade the CPU or add more memory without redesigning your whole board. This is great for future-proofing or creating product variants. If your design needs change, you might simply replace the SoM with a newer, pin-compatible module – as easy as swapping a card – rather than spinning a brand-new PCB. This modularity can extend the lifespan of an industrial or medical device by allowing incremental upgrades.

A few examples from Ezurio are our Open Standard Modules (OSM), MediaTek Genio powered SMARC SOMs, and NXP’s i.MX powered SMARC SOMs.

Comparing SOMs and SoCs

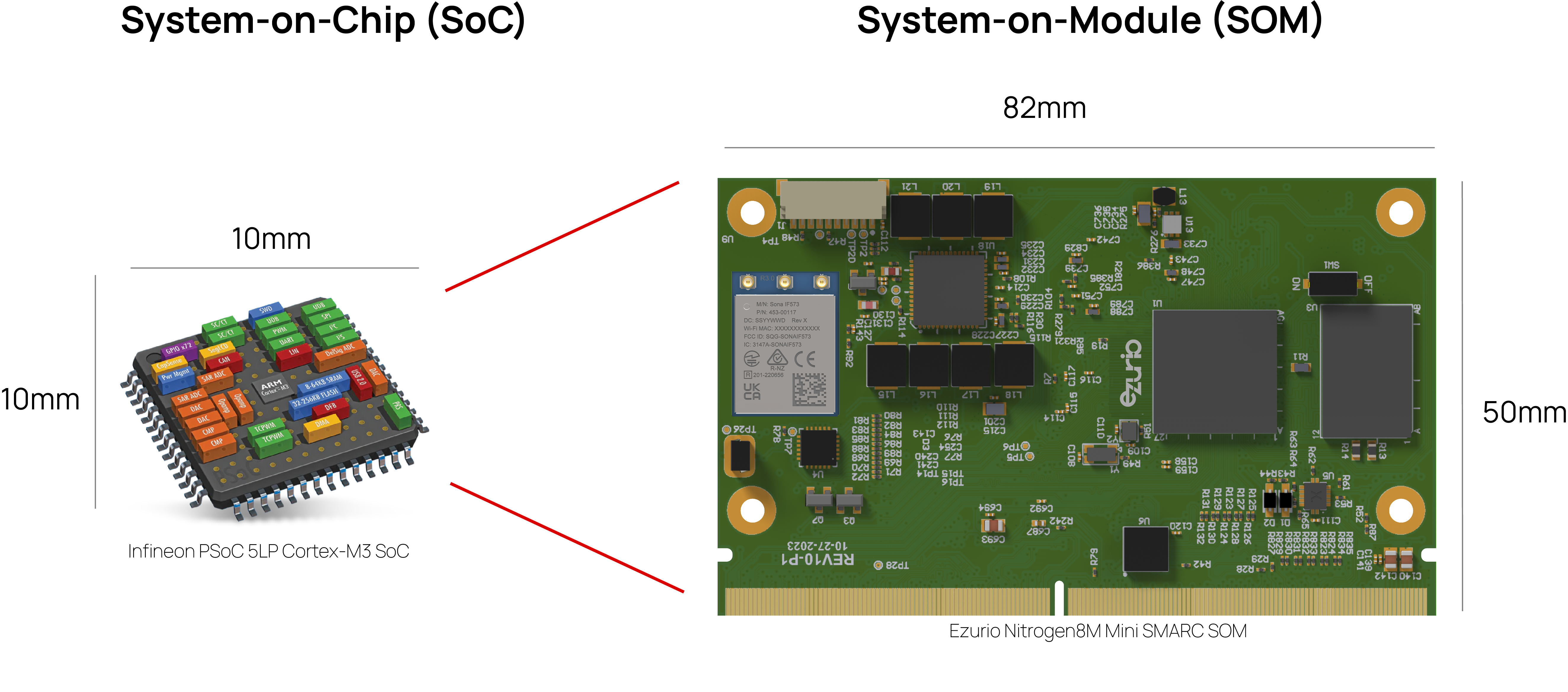

Now that we’ve defined each, let’s compare SoC and SoM differences in the context of embedded system design. Both SoCs and SoMs integrate a computing system, but they do so at different levels (chip-level vs board-level integration). This leads to distinct advantages and disadvantages in various aspects of design. Below, we break down the key factors:

Integration and Flexibility

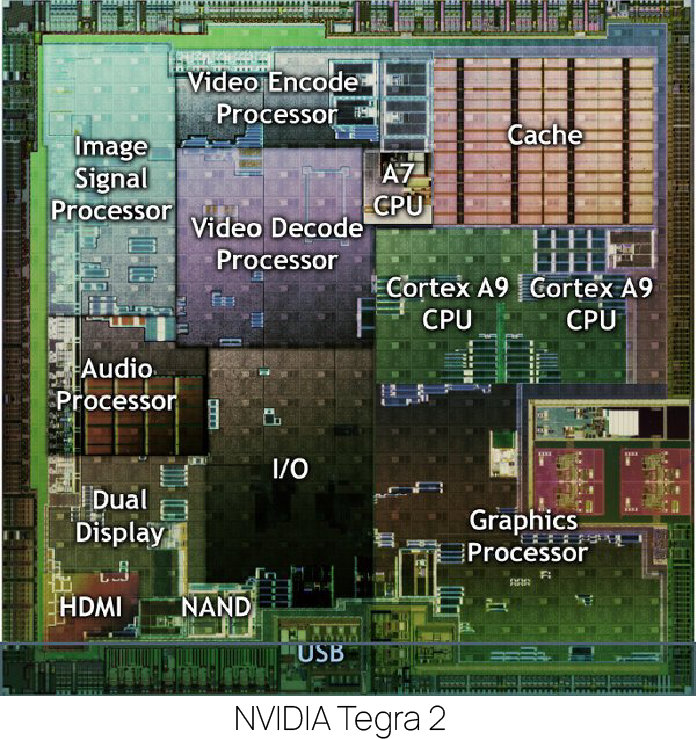

SoC: Highest level of integration at the silicon level – everything is on one chip. This is excellent for minimizing size and maximizing efficiency in a fixed design. However, it’s inherently inflexible: once you’ve chosen or designed an SoC, any significant change (like adding a new interface or a more powerful processor) would likely require a new SoC design or a different chip altogether, which means a major redesign of your hardware. An SoC-based design is tightly coupled to the specific chip’s capabilities, with little room for post-deployment modifications.

SoM: High integration at the module/board level, but with modularity built in. The SoM encapsulates a lot of complexity but still plugs into a socket or footprint on your carrier board. This means you can achieve flexibility that SoCs alone can’t. For example, if you want to upgrade your device’s processor or add more RAM, you might simply swap out to a newer SoM that is pin-compatible, rather than redesign everything. Users can even evaluate different processors by trying different SoMs on the same carrier board footprint. This flexibility accelerates development and future-proofs designs, especially useful in fast-evolving markets like IoT where you may need to update hardware capabilities every couple of years. In short: SoCs offer integration, while SoMs offer integration plus modularity. The modular approach increases flexibility without compromising the benefits of integration which is a big reason why SoMs are popular in industrial settings where long-term adaptability is needed.

Development Effort and Time-to-Market

SoC (Custom Board): Designing a product around a raw SoC means you are responsible for all the hardware integration. High-speed memory routing, RF design, power circuits, clock crystals, numerous peripherals – your engineering team must handle it all and ensure it works reliably. This requires specialized expertise in hardware design, signal integrity, PCB layout, and so on. It also means longer development cycles: each prototype iteration might reveal hardware bugs that need fixing, and the bring-up time (getting your OS and software running on the new custom hardware) can be significant. For complex SoC-based designs, it’s not uncommon to spend many months (or more) in hardware development and testing before the product is market-ready. In summary, SoC-based development tends to be slower and riskier upfront, but may pay off for very high-volume products later.

SoM: Incorporating a System-on-Module can dramatically shorten development time. Much of the difficult hardware design is already done and tested on the module. As one source puts it, all the complexity is encapsulated in the SoM, so the carrier board can be easily developed. Engineers don’t need as deep hardware expertise to get started – they can leverage the module vendor’s design. This means faster prototyping; teams can often get a system running on an eval carrier board and then just design a simple carrier for their specific needs. Time-to-market is reduced because you’re essentially integrating a pre-made subsystem. One vendor notes that using SoMs “significantly reduce[s] development complexity and cost”, making them ideal even for low-to-mid production volumes. Moreover, since many SoMs come with ready OS images and driver support, software development can proceed in parallel with hardware, further accelerating the schedule.

The trade-off in using a SoM is that you might not achieve the absolute lowest unit cost or the tightest integration possible, but you gain speed and reduce risk. Especially for startups or teams aiming to demonstrate a product quickly, getting to market faster with a module can outweigh the optimizations that a ground-up SoC design might allow.

Cost Considerations (Development vs. Production)

When comparing SoC vs SoM, cost needs to be looked at from two angles: the engineering/development cost and the per-unit production cost.

Development Cost: SoC-based projects usually entail high initial costs. Custom board design and debugging require expensive expertise, possibly specialized EDA tools, multiple PCB spins, and certification processes. This upfront investment is only justified if you plan to ship large volumes (to amortize the NRE – non-recurring engineering costs). In contrast, starting with a SoM has lower initial investment. The module may be pricey per unit, but you save on development of complex aspects like memory interfacing and RF tuning. There’s no need for costly one-off chip integration efforts when the SoM is already proven. One source summarizes that SoMs can be more cost-effective especially where production volumes do not justify the high setup costs of SoC development.

Production Cost: Here, the equation can flip depending on scale. SoCs excel in high-volume, cost-sensitive products – if you’re making millions of identical devices (think of a mainstream consumer gadget), even a few dollars saved per unit by using a bare SoC instead of a more expensive module adds up. So for mass-produced, standard products, an SoC approach often yields the lowest unit cost. In contrast, SoMs add cost per unit because you’re essentially purchasing an assembled sub-board with markup. For low to moderate volumes, this added cost might be acceptable or even cheaper when you factor in saved engineering effort. But for very large volumes, many companies will bite the bullet and do a custom SoC-based board to minimize recurring costs.

Another cost-related factor is certification and compliance. A SoM that is pre-certified can save a lot of money (and time) that you would otherwise spend on FCC/CE testing, PTCRB (for cellular), or other regulatory compliance for each new board design. This effectively reduces the hidden costs in development. Additionally, SoM vendors often handle supply chain and component sourcing for the module, which can reduce cost volatility for you – whereas if you design around an SoC, you must source all components (PMICs, RAM, etc.) yourself in production, and any supply issue can increase costs unexpectedly.

Performance, Power, and Size

Because an SoC is one integrated chip, it is typically optimized for performance and power efficiency in ways a more general module might not be. For battery-powered or ultra-compact devices, using the SoC directly on a custom board might achieve slightly better power usage and a smaller footprint than plugging in a module. SoCs are beneficial for applications where size and power are absolutely critical, such as wearables or tiny IoT sensors. In those scenarios, the added PCB and connectors of a SoM could be a limitation.

That said, many System-on-Modules are quite small (some stamp-sized or smaller) and use the same low-power SoCs internally, so the difference can be minor. It’s often possible to find a SoM that meets stringent size and power requirements if one looks carefully. Still, if you’re pushing the limits of miniaturization, a custom SoC design might be the only way to get exactly what you need.

In terms of performance, there is usually no inherent difference between an SoC and a SoM using that same SoC. A SoM won’t magically be slower; it contains the same processor, so performance depends on the chip inside. One nuance: SoMs sometimes use slightly less powerful SoCs that are designed for embedded modules, as opposed to the bleeding-edge chips found in flagship smartphones (which often are only available as standalone SoCs). But increasingly, SoMs are available for high-performance processors too. For example, there are modules with high-end application processors and even FPGAs, aimed at AI and vision processing. Thus, both approaches can satisfy performance needs, but SoCs might lead in ultra-optimized power-performance scenarios, whereas SoMs lead in convenience at a slight cost of overhead.

Reliability and Product Lifecycle

Reliability has a couple of meanings here: hardware reliability in the field, and consistency/maintenance over the product’s lifecycle.

Hardware Reliability: An SoC, being highly integrated, reduces the number of external solder joints and components, which can improve physical reliability (fewer things to break or connectors to fail). However, a System-on-Module is typically a professionally designed and tested unit, often built to meet industry standards for shock, vibration, and temperature. In fact, SoMs are usually designed, manufactured, and tested to meet stringent industry reliability standards from the get-go. This means that if you use a reputable SoM, you inherit a level of robustness and validation that might be hard to achieve on the first revision of a custom design. The module likely has already gone through temperature cycling, EMC testing, etc., so you start from a known good baseline. This can reduce the risk of hardware failures in the field for your product. In industrial and medical contexts, where failure is not an option, that proven reliability is a big plus for SoMs.

Lifecycle and Longevity: Industrial and medical devices often need to be supported for many years, sometimes a decade or more. Here, SoM vendors often shine: they tend to provide long-term support for their modules, including documentation, software updates, and a commitment to supply modules or equivalent replacements for a long time. Many SoM families are advertised with 7, 10, or even 15+ year availability. For example, a module based on an NXP industrial processor might be guaranteed for 10-15 years of supply. This long lifecycle support means you can design it into a medical device and not worry about redesign for obsolescence for a while. Additionally, because of the modular swap-out ability, if a component on the SoM does become obsolete, the vendor might offer an updated module as a drop-in replacement. On the flip side, if you roll your own SoC-based board, managing component obsolescence is on you – if the SoC or a key component is discontinued, you may face a redesign.

Upgradability: in industrial settings, technology evolves, but machines might be deployed for 20 years. SoMs allow incremental upgrades to keep systems up-to-date. One real-world example is using an upgraded SoM in older industrial equipment to add new features like better connectivity or AI processing, thereby extending the life of the equipment without a full overhaul. This kind of upgrade path is far easier with modules than with fixed SoCs.

Vendor Lock-in Risk: A note on reliability of supply: choosing a SoM does mean you rely on that vendor. If the vendor goes out of business or discontinues the module, you could be in a tough spot (needing to find a pin-compatible replacement or redesign). Mitigating this means choosing SoM vendors with a good track record and industry standard form factors (like SMARC, COM Express, OSM, etc., which at least gives some cross-vendor compatibility). With an SoC and custom design, you are dependent on the chip manufacturer to keep making that SoC (and they eventually will EOL it too). So either way, long-term availability is a concern – just be sure to plan for it.

Pros and Cons

The following table outlines the advantages and disadvantages of SOM and SoC, providing insights on development time, risk, initial cost, and suitability for different types of applications: